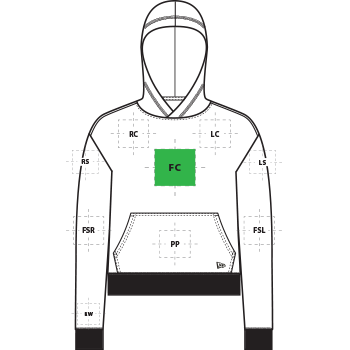

| Front Decoration Dimensions | |||

|---|---|---|---|

| FC | Full Chest | 10" H x 10" W | Primary |

| LC | Left Chest | 4"H x 4"W | |

| PP | Pouch Pocket | 5"H x 8"W | |

| RC | Right Chest | 4"H x 4"W | |

| Back Decoration Dimensions | |||

|---|---|---|---|

| BA | Back | 12"H x 12"W | |

| UB | Upper Back | 4"H x 12"W | |

| Sleeve Decoration Dimensions | |||

|---|---|---|---|

| FSL | Full Sleeve Left | 4"H x 14"W | |

| FSR | Full Sleeve Right | 4"H x 14"W | |

| RW | Right Wrist | 4"H x 4"W | |

| Hood Decoration Dimensions | |||

|---|---|---|---|

| LHS | Left Hood Side | 5"H x 5"W | |

| RHS | Right Hood Side | 5"H x 5"W | |

Decoration TechniquesClick the icon for details

Essential Product Information

Due to the nature of cotton/polyester blends, special care must be taken throughout the decoration process when heat is applied for curing. Please consult with your decorator or material supplier.

Tips From Our Experts By Decoration Technique

Embroidery is the art of embellishing a piece of apparel with a needle and thread or yarn creating stunning visual representations of various types of art. This is achieved by converting logos in a digitizing software and using various stitch patterns, angles, density and stitch types to create depth, movement and detail. Thread can be made from many materials. The most commonly used threads are polyester and rayon. There are also options such as metallic, cotton, nylon, silk and even Nomex thread for fire resistance. Embroidery has a very high-perceived value and is popular for use on most apparel, bags, hats, luggage, blankets and more!

An imprinting method in which the image is transferred to the fabric. Ink is squeegeed through a stenciled screen stretched over a frame and then cured in a dryer.

Low Cure ink, Bleed Blockers needed, *Please consult with your decorator, equipment, and consumable supplier.*

A graphic, name and or number applied to a textile with a heat press. Great for quantities of any size, sports name and numbering, fashion, performance wear, print on demand programs and on-site decorating events.

Direct to garment (DTG) is the art of printing a graphic directly onto a piece of apparel using digital ink jet technology. A DTG Printer is similar to a large ink jet printer that uses specialized inks and garment pre-treatments that allow the ink to adhere and stay vibrant. This decoration method is ideal for art that is designed in full color with fades, shadows, gradients, high detail and photo realistic elements. DTG is primarily used on cotton fabrics, however recent advancements in technology have made printing on cotton/poly blends and 100% polyester possible.

Pad printing uses a soft silicone pad to transfer an image taken from a plate etched with a reversed logo, similar to a rubber stamp. Images can be very small and detailed and can be up to 5½ inches in diameter. Pad printers are capable of printing up to six colors, however most industry printers use one to two colors at most when printing on apparel. Pad printing is a popular trend for tagless label printing. The prints are soft, durable and capable of high and low volume production. Pad printing is great for sling bags, totes and other items that are difficult to decorate, as well as styles that are heat sensitive.

specialty frames and applications that are specific to a shop's setup and equipment.